TRENDING HASHTAG: #MACHINE

Trending Posts

-

-

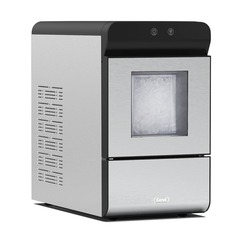

GEVI Ice Maker

Gevi has since become a renowned global brand committed to producing various smallappliances that provide practical solutions in cooking, ice-making, and housekeeping. Our exceptional coffeemachines and ice makers have swiftly climbed to the top of... moreGevi has since become a renowned global brand committed to producing various smallappliances that provide practical solutions in cooking, ice-making, and housekeeping. Our exceptional coffeemachines and ice makers have swiftly climbed to the top of Amazon's best-seling list, a testament to our unwavering commitment to quality and innovation. https://gevi.com/ #sonic #style #ice #machine #for #home #best #coffee #machine less

Aug 19

Explore GEVI household home nugget ice maker machines, espresso, drip and pour-over coffee maker machines, vacuum cleaners, accessories and support to enhance your quality of life.

-

GEVI Ice Maker

GEVI Household Nugget Ice Maker https://gevi.com/collections/ice-makers #sonic #style #ice #machine #for #home

Aug 19

Experience the cool life with Gevi's Home Countertop Ice Maker & Machine! Create nugget ice at home with this portable and compact machine. Whether for chilling beverages or enjoying chewable ice, Gevi brings the ultimate convenience to your kitchen counte

-

GEVI Ice Maker

GEVI Household Countertop Nugget Ice Maker Machine With Viewing Window https://gevi.com/collections/ice-makers/products/gevi-household-countertop-nugget-ice-maker-with-viewing-window?variant=47441263919410 #sonic #style #ice #machine #for #home

Aug 16

Chill out with GEVI's Household Countertop Nugget Ice Maker! Portable and sleek, it fits perfectly in your kitchen. Enjoy refreshing pebble ice in minutes and watch the magic happen through the viewing window. Elevate your drinks with GEVI.

-

Zed Longxin laser

laser tube bevel cutting machine: https://lxcut.net/product/lx-t12/

#lase r#cutter #machine

May 13

Do you want to report this? Why didn't you like it?

-

wzcfmachine wzcf machine

Single Straw Packing Machine

https://www.wzcfmachine.com/products/single-straw-packing-machine/

#paper #straw #packing #machine

Our paper straw single packaging machine is designed for environmental protection. Using advanced automation technology,... moreSingle Straw Packing Machine

https://www.wzcfmachine.com/products/single-straw-packing-machine/

#paper #straw #packing #machine

Our paper straw single packaging machine is designed for environmental protection. Using advanced automation technology, each paper straw can be individually packaged quickly and accurately to ensure its hygiene and safety. Whether it's a restaurant, cafe or fast food restaurant, it can easily handle heavy use needs. Choose our pindividual straw packing machine to make every use full of environmental awareness and let us protect our earth together.

How Does Our Individual Straw Ping Machine Work?

Adopted with PLC controller; the main motor is equipped with variable frequency speed regulation; touch screen man-machine interface. Easy for parameters setting & operating.

The cutting section of our straw manufacturing machine adopted with numerical multi-blades cutting system. Servo synchronous tracking cutting system makes it higher precision and multi-blades cutting makes it higher efficient.

The single straw packing machine's body and main spare parts are made of stainless steel instead of painting. Ensure the hygiene and environmental protection of the products.

What to Expect from Our Paper Straw-Making Machines?

Embrace eco-friendliness with confidence by choosing our advanced individual straw packing machine from Chuangfeng. Here's what you can expect:

Cutting-Edge Technology: Our single straw packing machines incorporate state-of-the-art technology, ensuring the production of top-quality paper straws that are sturdy and durable.

Environmentally Conscious Production: Start your journey towards environmental conservation with small, yet impactful steps. Our paper straw packing machine craft paper straws, providing a sustainable alternative to traditional plastic straws.

High-Quality Output: Experience the excellence of Chuangfeng's machinery through the production of high-quality, reliable paper straws. Enjoy your drinks guilt-free, knowing you're contributing to a greener planet.

Expertise in Manufacturing: As one of the most professional paper straw and paper tube machines suppliers in China, Chuangfeng brings years of experience and expertise to the table, ensuring reliable and efficient equipment.

Unique Advantages: Benefit from Chuangfeng's distinctive advantages in paper straw and tube equipment manufacturing, setting us apart from others in the industry.

Make a conscious choice for the environment—choose Chuangfeng's Paper Straw Making Machines and make sustainability a way of life. less

May 8

-

wzcfmachine wzcf machine

Paper Straw Making Machine

https://www.wzcfmachine.com/products/paper-straw-making-machine/

#machine #to #make #paper #straws

Environmentally friendly, start with a small paper straw. Our machine to make paper straws uses advanced technology to... morePaper Straw Making Machine

https://www.wzcfmachine.com/products/paper-straw-making-machine/

#machine #to #make #paper #straws

Environmentally friendly, start with a small paper straw. Our machine to make paper straws uses advanced technology to produce high-quality, sturdy, and durable paper straws, allowing you to enjoy your drinks while also contributing to the earth. Let us work together to protect the environment with practical actions, starting with using paper straws. Choose our paper straw manufacturing machine and make environmental protection a way of life.

Chuangfeng, one of the most professional paper straw and paper tube machine suppliers in China, has a lot of experience in China paper straw and tube equipment manufacturing. With years of production and practice, Chuangfeng has formed its advantages different from other paper straw and paper tube machine.

How Does Our Paper Straw-Making Machine Work?

Our paper straw-making machine is a specialized piece of equipment designed to produce paper straws efficiently and effectively. Here's a detailed explanation of how it operates:

The paper is rapidly fed through the paper feeder while the glue feeder ensures a consistent temperature to automatically stabilize the glue amount.

The High-speed paper straw machine winds and forms the adhesive paper layer, enabling multi-section cutting in a single operation.

Paper-making straws are dried by the electric dryer before being shaped into bendable grooves by the flexible bending machine.

The straws are then transported to the Paper straw dryer via a conveyor belt for further drying.

Finally, the Packaging machine processes the bendable straws into a U-shape, slices the bottom to create a bevel cut, and individually packs the U-shaped paper straws using BOPP film.

What to Expect from Our Paper Straw Making Machines?

To ensure environmental protection, paper straws produced by paper straw-making machines, particularly biodegradable ones, surpass plastic straws in sustainability. With the growing focus on environmentalism, these straws are poised to become the prevailing choice in the future.

As a result, there will be a significant increase in demand for paper straw-making machines compared to those for plastic straws. Currently, numerous industries are entering the paper straw manufacturing sector due to the substantial demand across various industries.

If you're considering establishing a paper straw manufacturing unit, the necessity for a paper straw-making machine is evident. These machines come in a variety of types, including manual, semi-automatic, and fully automatic models.

Available at different price points, you can select a machine that aligns with your business requirements and financial constraints. Purchasing from Chuangfeng, a reputable company, ensures access to high-quality, high-performance, and high-capacity paper straw-making machines for your operations.

Features of Paper Drinking Straws

The paper drinking straws crafted using our paper straw-making machine boast the following characteristics:

Longevity: When immersed in a beverage at a steady temperature, these paper straws can maintain their integrity for 2-3 hours without succumbing to sogginess. However, exposure to extremely hot or cold drinks may shorten their lifespan compared to usage at room temperature.

Environmentally Friendly: Paper straws unquestionably outshine plastic alternatives in terms of environmental friendliness. Increased usage of paper straws can significantly reduce the adverse impact on marine life, leading to a decline in deaths caused by plastic pollution. Studies indicate that even when disposed of outdoors, paper straws decompose entirely within 6 months, posing no threat to the environment.

Coated Paper Drinking Straws: Our paper straws are coated with water-based glue, also known as water-based adhesives, to enhance their durability and performance.

Paper Straw Making Machine Cost

The price of a paper straw manufacturing machine in China can vary significantly based on factors such as the machine's automatic paper splicing function and overall quality.

To better understand the pricing of paper straw-making machines in China, it's essential to determine your specific requirements for the machine.

Comparatively, a plastic straw costs approximately RMB 0.03, while a paper straw typically costs around RMB 0.1, representing a difference of more than threefold.

Indeed, paper straws come with a higher cost, and there is room for improvement in terms of user experience. However, certain industry insiders and experts suggest that finding environmentally friendly alternatives to plastic straws is feasible through the breakthrough and development of new materials and technologies.

Materials such as biodegradable bioplastics, paper, bamboo, wheat, various plant stalks, glass, metal, and other recyclable products can serve as substitutes for plastic, contributing to environmental sustainability. less

May 8

-

wzcfmachine wzcf machine

U Shape Paper Straw Production Line

https://www.wzcfmachine.com/u-shape-paper-straw-production-line.html

#paper #straw #making #machine

A U-shaped paper straw production line produces paper straws by winding, cutting, drying, bending, and packaging at... moreU Shape Paper Straw Production Line

https://www.wzcfmachine.com/u-shape-paper-straw-production-line.html

#paper #straw #making #machine

A U-shaped paper straw production line produces paper straws by winding, cutting, drying, bending, and packaging at one time.

U Shape Paper Straw Production Process:

1. The paper is swiftly fed through the paper feeder at high velocity, while the glue feeder automatically applies glue at a consistent temperature to stabilize the amount.

2. The CFXG-80 high-speed paper straw-making machine high-speed paper straw machine winds and forms the adhesive paper layer, enabling multi-section cutting in a single operation.

3. Following drying in the CFHG-50 paper straw dryer, and the CFBD-50 flexible bending machine creates bendable corrugations in the paper straws.

4. Finally, the CFPK-033 packaging machine processes the bendable straws into a U-shaped form, slices the straws into sharp shapes, and individually packs the U-shaped paper straws using BOPP film.

Key Components of U-shape Paper Straw Production Line:

Paper straw making machine: This machine forms the basic structure of the paper straw using paper rolls, adhesive, and other necessary materials.

Cutting machine: Responsible for cutting the paper straws to the desired length, including the U-shaped bend.

Drying machine: Used to dry the paper straws after production to ensure they maintain their structural integrity.

Bending machine: This machine adds the U-shaped bend to the paper straws, giving them their distinctive shape.

Packaging machine: Finally, the paper straws are packaged into bundles or boxes for distribution and sale.

The entire production line can realize high-intelligence production, and the entire assembly line can operate automatically, enabling one person to operate multiple machines. During the production process, failures such as pipe blockage and paper break will automatically stop, without the need for personnel to keep watch. less

May 8

-

wzcfmachine wzcf machine

Paper Straw Making Machine

https://www.wzcfmachine.com/products/paper-straw-making-machine/

#straw #maker #machine

Environmentally friendly, start with a small paper straw. Our paper straw maker machine uses advanced technology to produce... morePaper Straw Making Machine

https://www.wzcfmachine.com/products/paper-straw-making-machine/

#straw #maker #machine

Environmentally friendly, start with a small paper straw. Our paper straw maker machine uses advanced technology to produce high-quality, sturdy, and durable paper straws, allowing you to enjoy your drinks while also contributing to the earth. Let us work together to protect the environment with practical actions, starting with using paper straws. Choose our paper straw manufacturing machine and make environmental protection a way of life.

Chuangfeng, one of the most professional paper straw and paper tube machine suppliers in China, has a lot of experience in China paper straw and tube equipment manufacturing. With years of production and practice, Chuangfeng has formed its advantages different from other paper straw and paper tube machine.

How Does Our Paper Straw-Making Machine Work?

Our paper straw-making machine is a specialized piece of equipment designed to produce paper straws efficiently and effectively. Here's a detailed explanation of how it operates:

The paper is rapidly fed through the paper feeder while the glue feeder ensures a consistent temperature to automatically stabilize the glue amount.

The High-speed paper straw machine winds and forms the adhesive paper layer, enabling multi-section cutting in a single operation.

Paper-making straws are dried by the electric dryer before being shaped into bendable grooves by the flexible bending machine.

The straws are then transported to the Paper straw dryer via a conveyor belt for further drying.

Finally, the Packaging machine processes the bendable straws into a U-shape, slices the bottom to create a bevel cut, and individually packs the U-shaped paper straws using BOPP film.

What to Expect from Our Paper Straw Making Machines?

To ensure environmental protection, paper straws produced by paper straw-making machines, particularly biodegradable ones, surpass plastic straws in sustainability. With the growing focus on environmentalism, these straws are poised to become the prevailing choice in the future.

As a result, there will be a significant increase in demand for paper straw-making machines compared to those for plastic straws. Currently, numerous industries are entering the paper straw manufacturing sector due to the substantial demand across various industries.

If you're considering establishing a paper straw manufacturing unit, the necessity for a paper straw-making machine is evident. These machines come in a variety of types, including manual, semi-automatic, and fully automatic models.

Available at different price points, you can select a machine that aligns with your business requirements and financial constraints. Purchasing from Chuangfeng, a reputable company, ensures access to high-quality, high-performance, and high-capacity paper straw-making machines for your operations.

Features of Paper Drinking Straws

The paper drinking straws crafted using our paper straw-making machine boast the following characteristics:

Longevity: When immersed in a beverage at a steady temperature, these paper straws can maintain their integrity for 2-3 hours without succumbing to sogginess. However, exposure to extremely hot or cold drinks may shorten their lifespan compared to usage at room temperature.

Environmentally Friendly: Paper straws unquestionably outshine plastic alternatives in terms of environmental friendliness. Increased usage of paper straws can significantly reduce the adverse impact on marine life, leading to a decline in deaths caused by plastic pollution. Studies indicate that even when disposed of outdoors, paper straws decompose entirely within 6 months, posing no threat to the environment.

Coated Paper Drinking Straws: Our paper straws are coated with water-based glue, also known as water-based adhesives, to enhance their durability and performance.

Paper Straw Making Machine Cost

The price of a paper straw manufacturing machine in China can vary significantly based on factors such as the machine's automatic paper splicing function and overall quality.

To better understand the pricing of paper straw-making machines in China, it's essential to determine your specific requirements for the machine.

Comparatively, a plastic straw costs approximately RMB 0.03, while a paper straw typically costs around RMB 0.1, representing a difference of more than threefold.

Indeed, paper straws come with a higher cost, and there is room for improvement in terms of user experience. However, certain industry insiders and experts suggest that finding environmentally friendly alternatives to plastic straws is feasible through the breakthrough and development of new materials and technologies.

Materials such as biodegradable bioplastics, paper, bamboo, wheat, various plant stalks, glass, metal, and other recyclable products can serve as substitutes for plastic, contributing to environmental sustainability. less

May 8

-

wzcfmachine wzcf machine

U Shape Paper Straw Production Line

https://www.wzcfmachine.com/u-shape-paper-straw-production-line.html

#straw #paper #machine

A U-shaped paper straw production line produces paper straws by winding, cutting, drying, bending, and packaging at one... moreU Shape Paper Straw Production Line

https://www.wzcfmachine.com/u-shape-paper-straw-production-line.html

#straw #paper #machine

A U-shaped paper straw production line produces paper straws by winding, cutting, drying, bending, and packaging at one time.

U Shape Paper Straw Production Process:

1. The paper is swiftly fed through the paper feeder at high velocity, while the glue feeder automatically applies glue at a consistent temperature to stabilize the amount.

2. The CFXG-80 high-speed paper straw-making machine high-speed paper straw machine winds and forms the adhesive paper layer, enabling multi-section cutting in a single operation.

3. Following drying in the CFHG-50 paper straw dryer, and the CFBD-50 flexible bending machine creates bendable corrugations in the paper straws.

4. Finally, the CFPK-033 packaging machine processes the bendable straws into a U-shaped form, slices the straws into sharp shapes, and individually packs the U-shaped paper straws using BOPP film.

Key Components of U-shape Paper Straw Production Line:

Paper straw making machine: This straw paper machine forms the basic structure of the paper straw using paper rolls, adhesive, and other necessary materials.

Cutting machine: Responsible for cutting the paper straws to the desired length, including the U-shaped bend.

Drying machine: Used to dry the paper straws after production to ensure they maintain their structural integrity.

Bending machine: This machine adds the U-shaped bend to the paper straws, giving them their distinctive shape.

Packaging machine: Finally, the paper straws are packaged into bundles or boxes for distribution and sale.

The entire production line can realize high-intelligence production, and the entire assembly line can operate automatically, enabling one person to operate multiple machines. During the production process, failures such as pipe blockage and paper break will automatically stop, without the need for personnel to keep watch. less

May 8

-

wzcfmachine wzcf machine

Paper Straw Making Machine

https://www.wzcfmachine.com/products/paper-straw-making-machine/

#paper #straw #machine #china

Environmentally friendly, start with a small paper straw. Our paper straw maker machine uses advanced technology to produce... morePaper Straw Making Machine

https://www.wzcfmachine.com/products/paper-straw-making-machine/

#paper #straw #machine #china

Environmentally friendly, start with a small paper straw. Our paper straw maker machine uses advanced technology to produce high-quality, sturdy, and durable paper straws, allowing you to enjoy your drinks while also contributing to the earth. Let us work together to protect the environment with practical actions, starting with using paper straws. Choose our paper straw manufacturing machine and make environmental protection a way of life.

Chuangfeng, one of the most professional paper straw machine manufacturers in China, has a lot of experience in China paper straw and tube equipment manufacturing. With years of production and practice, Chuangfeng has formed its advantages different from other paper straw and paper tube machine.

How Does Our Paper Straw-Making Machine Work?

Our paper straw machine china is a specialized piece of equipment designed to produce paper straws efficiently and effectively. Here's a detailed explanation of how it operates:

The paper is rapidly fed through the paper feeder while the glue feeder ensures a consistent temperature to automatically stabilize the glue amount.

The High-speed paper straw machine winds and forms the adhesive paper layer, enabling multi-section cutting in a single operation.

Paper-making straws are dried by the electric dryer before being shaped into bendable grooves by the flexible bending machine.

The straws are then transported to the Paper straw dryer via a conveyor belt for further drying.

Finally, the Packaging machine processes the bendable straws into a U-shape, slices the bottom to create a bevel cut, and individually packs the U-shaped paper straws using BOPP film.

What to Expect from Our Paper Straw Making Machines?

To ensure environmental protection, paper straws produced by paper straw-making machines, particularly biodegradable ones, surpass plastic straws in sustainability. With the growing focus on environmentalism, these straws are poised to become the prevailing choice in the future.

As a result, there will be a significant increase in demand for paper straw-making machines compared to those for plastic straws. Currently, numerous industries are entering the paper straw manufacturing sector due to the substantial demand across various industries.

If you're considering establishing a paper straw manufacturing unit, the necessity for a paper straw-making machine is evident. These machines come in a variety of types, including manual, semi-automatic, and fully automatic models.

Available at different price points, you can select a machine that aligns with your business requirements and financial constraints. Purchasing from Chuangfeng, a reputable company, ensures access to high-quality, high-performance, and high-capacity paper straw-making machines for your operations.

Features of Paper Drinking Straws

The paper drinking straws crafted using our paper straw-making machine boast the following characteristics:

Longevity: When immersed in a beverage at a steady temperature, these paper straws can maintain their integrity for 2-3 hours without succumbing to sogginess. However, exposure to extremely hot or cold drinks may shorten their lifespan compared to usage at room temperature.

Environmentally Friendly: Paper straws unquestionably outshine plastic alternatives in terms of environmental friendliness. Increased usage of paper straws can significantly reduce the adverse impact on marine life, leading to a decline in deaths caused by plastic pollution. Studies indicate that even when disposed of outdoors, paper straws decompose entirely within 6 months, posing no threat to the environment.

Coated Paper Drinking Straws: Our paper straws are coated with water-based glue, also known as water-based adhesives, to enhance their durability and performance.

Paper Straw Making Machine Cost

The price of a paper straw manufacturing machine in China can vary significantly based on factors such as the machine's automatic paper splicing function and overall quality.

To better understand the pricing of paper straw-making machines in China, it's essential to determine your specific requirements for the machine.

Comparatively, a plastic straw costs approximately RMB 0.03, while a paper straw typically costs around RMB 0.1, representing a difference of more than threefold.

Indeed, paper straws come with a higher cost, and there is room for improvement in terms of user experience. However, certain industry insiders and experts suggest that finding environmentally friendly alternatives to plastic straws is feasible through the breakthrough and development of new materials and technologies.

Materials such as biodegradable bioplastics, paper, bamboo, wheat, various plant stalks, glass, metal, and other recyclable products can serve as substitutes for plastic, contributing to environmental sustainability. less

May 8

-

wzcfmachine wzcf machine added new photos.

Paper Tube Labeling Machine

https://www.wzcfmachine.com/products/paper-tube-labeling-machine/

#paper #tube #labeling #machine

The automatic paper tube labeling machine is a specialized piece of equipment designed to apply labels to paper tubes... morePaper Tube Labeling Machine

https://www.wzcfmachine.com/products/paper-tube-labeling-machine/

#paper #tube #labeling #machine

The automatic paper tube labeling machine is a specialized piece of equipment designed to apply labels to paper tubes accurately and efficiently. This machine is commonly used in industries such as packaging, cosmetics, food and beverage, pharmaceuticals, and more, where labeled paper tubes are required.

Here's a brief overview of its functionality:

Material Loading: The process begins by loading the paper tubes into the machine. This can be done manually or automatically, depending on the machine model.

Label Application: The machine applies labels to the paper tubes using a variety of methods, such as pressure-sensitive adhesives, hot melt adhesives, or shrink sleeve labeling. The labels can be applied to any part of the tube, including the body, cap, or bottom.

Precision and Speed: The machine is designed to apply labels accurately and quickly, ensuring that each label is perfectly positioned and adhered. This precision and speed are crucial in maintaining high-quality standards and meeting production deadlines.

Quality Control: Many machines come with built-in quality control features that check for any irregularities or defects in the labeled tubes. This ensures that only high-quality products reach the end of the production line.

Collection: After the tubes are labeled, they are collected in a bin or on a conveyor belt. Some machines also have an automatic sorting feature that separates the tubes based on their sizes or labels.

As a common type of paper tube machine, the paper tube labeling machine is known for its efficiency, accuracy, and speed, capable of labeling large quantities of tubes in a short time. It's a valuable asset for businesses looking to streamline their production process and improve productivity. The machine's robust construction also ensures long-term durability, making it a worthwhile investment.

How Does Paper Tube Labeling Machine Ensure Accurate Branding?

The Paper Tube Labeling Machine plays a crucial role in ensuring accurate branding, which is vital for product recognition and marketing. Here’s how it achieves this:

Precision Label Placement: The machine is designed to apply labels accurately on the paper tubes. It ensures that each label is perfectly positioned, maintaining consistency across all products. This precision is crucial for maintaining a professional and consistent brand image.

High-Quality Label Application: The machine applies labels using various methods such as pressure-sensitive adhesives, hot melt adhesives, or shrink sleeve labeling. These methods ensure that the labels are securely adhered to the tubes and won’t peel off, fade, or get damaged during handling or transportation.

Versatility: The machine can handle a wide range of paper tube sizes and label designs. This versatility allows businesses to use different labels for different products, ensuring accurate branding for each product line.

Speed and Efficiency: The paper core machine can label a large number of tubes in a short time, ensuring that high volumes of products are branded accurately and quickly. This efficiency is crucial for meeting production deadlines and maintaining a steady supply of branded products in the market.

Quality Control: Many models come with built-in quality control features that check for any irregularities or defects in the labeled tubes. This ensures that only high-quality, accurately branded products reach the end of the production line.

In conclusion, the Paper Tube Labeling Machine ensures accurate branding by providing precision label placement, high-quality label application, versatility, speed, and quality control. It’s an invaluable tool for businesses looking to maintain a consistent and professional brand image.

Working Principle of Paper Tube Labeling Machine

The Paper Tube Labeling Machine operates on a sophisticated principle to ensure precise and efficient application of labels onto paper tubes in various industries:

Sensor Technology: Equipped with advanced sensors, the machine detects the position and orientation of each paper tube, ensuring accurate label placement.

Label Dispensing Mechanism: The labeling machine utilizes a precision label dispensing system that releases labels at the right moment, synchronizing with the speed and movement of the paper tubes.

Adaptive Adjustments: To accommodate different tube sizes, the machine often features adjustable settings, allowing quick and easy configuration for various diameters and lengths.

Roller and Belt System: A combination of rollers and belts moves the paper tubes through the labeling process, maintaining stability and preventing misalignment.

User-Friendly Interface: Typically, these machines come with an intuitive interface, enabling operators to set parameters, monitor the process, and make adjustments seamlessly.

High-Speed Operation: Designed for efficiency, the Paper Tube Labeling Machine operates at high speeds, contributing to increased production rates while maintaining labeling precision. less

May 8

-

wzcfmachine wzcf machine

Paper Slitter Rewinder

https://www.wzcfmachine.com/products/paper-slitter-rewinder/

#paper #slitting #and #rewinding #machine #manufacturers

A paper tube cutting machine is a versatile and essential machine used in the paper industry. It is designed... morePaper Slitter Rewinder

https://www.wzcfmachine.com/products/paper-slitter-rewinder/

#paper #slitting #and #rewinding #machine #manufacturers

A paper tube cutting machine is a versatile and essential machine used in the paper industry. It is designed to cut large rolls of paper into smaller, more manageable rolls of desired width and length. This machine is crucial in various sectors, including printing, packaging, and converting industries.

Unwinding: The process begins with loading a large roll of paper onto the unwinding shaft. The machine then unwinds the paper roll at a controlled speed.

Slitting: The unwound paper is then passed through sharp blades or rotary knives that slit the paper into smaller widths. The number of blades can be adjusted based on the number of rolls required.

Rewinding: The slit paper is then rewound onto separate cores to form smaller rolls. The tension and speed of rewinding can be controlled to ensure the rolls are wound tightly and evenly.

Cutting: Some machines also have an integrated cutting mechanism that cuts the rewound rolls to the desired length.

Quality Control: Many Paper Slitter Rewinders come with built-in inspection systems that check for defects or irregularities in the paper.

The Paper Slitter Rewinder is known for its high efficiency, precision, and speed. It can handle a wide range of paper types and thicknesses, making it a versatile choice for businesses. With its robust construction and advanced features, this paper core machine ensures smooth and consistent operation, enhancing productivity and reducing waste. Whether you’re a small print shop or a large paper mill, a Paper Slitter Rewinder can be a valuable addition to your production line.

Paper Slitter Rewinder: Enhancing Efficiency in Manufacturing

The Paper Slitter Rewinder is a game-changer in the manufacturing industry, significantly enhancing efficiency and productivity. This machine is designed to transform large rolls of paper into smaller ones, tailored to specific requirements. Here’s how it contributes to manufacturing efficiency:

High-Speed Operation: paper tube winder machine operate at high speeds, capable of processing large volumes of paper in a short time. This speed significantly reduces production time, enabling businesses to meet high demand quickly.

Precision Cutting: With adjustable blades, the machine ensures precise and consistent cuts every time. This precision eliminates waste from inaccurate cuts, saving materials and costs.

Automation: Many models come with automated features, reducing the need for manual intervention. This automation not only saves labor costs but also minimizes human error, ensuring consistent quality.

Quality Control: With built-in inspection systems, the machine can detect and rectify defects or irregularities in the paper. This feature ensures that only high-quality paper rolls reach the end of the production line.

Space Efficiency: Despite its robust capabilities, the Paper Slitter Rewinder has a compact design that saves valuable floor space in manufacturing facilities.

By investing in a Paper Slitter Rewinder, businesses can significantly enhance their manufacturing efficiency. This core pipe-making machine not only speeds up the production process but also ensures the consistent quality of the final product, leading to increased customer satisfaction and profitability.

Paper Slitter Rewinders for Every Industry Need

Paper slitter rewinders play a pivotal role across diverse industries, addressing unique needs with precision and efficiency:

Printing Industry: In printing, these machines facilitate the production of custom-sized paper rolls, optimizing printing processes and reducing waste.

Packaging Sector: The packaging industry benefits from the adaptability of paper slitter rewinders, ensuring the creation of tailored rolls for various packaging applications, enhancing efficiency and minimizing material costs.

Converting Industries: Paper converting relies on these machines to transform large paper rolls into smaller, usable rolls with specific dimensions, meeting the requirements of different product lines.

Flexibility in Width and Length: The versatility of paper slitter rewinders allows for the customization of roll width and length, catering to the unique specifications of each industry and product.

Enhanced Productivity: With precise cutting and rewinding capabilities, these machines contribute to increased productivity, reducing downtime and enhancing overall operational efficiency in multiple sectors. less

May 8

-

wzcfmachine wzcf machine added new photos.

Paper Tube Cutting Machine

https://www.wzcfmachine.com/products/paper-tube-cutting-machine/

#small #paper #tube #cutting #machine

A small paper tube cutting machine is a specialized piece of equipment designed to cut paper tubes or cores into precise... morePaper Tube Cutting Machine

https://www.wzcfmachine.com/products/paper-tube-cutting-machine/

#small #paper #tube #cutting #machine

A small paper tube cutting machine is a specialized piece of equipment designed to cut paper tubes or cores into precise lengths. This machine is essential in various industries, including textile, paper, printing, packaging, and more.

Here's a brief overview of its functionality:

Material Loading: The process begins by loading the paper tube or core into the machine. This can be done manually or automatically, depending on the machine model.

Setting the Length: The operator sets the desired length for the cut. Most machines have a digital control panel where you can input the exact measurements, ensuring high precision in every cut.

Cutting Process: The machine uses a sharp, durable blade to cut the paper tube. The cutting can be done either by a rotating blade, a guillotine-style blade, or a saw blade, depending on the machine model and the thickness of the paper tube.

Collection: After the tubes are cut, they are collected in a bin or on a conveyor belt. Some machines also have an automatic sorting feature that separates the tubes based on their sizes.

Quality Control: Many machines come with built-in quality control features that check for any irregularities or defects in the cut tubes.

The Paper Tube Cutting Machine is known for its efficiency, accuracy, and speed, capable of producing large quantities of cut tubes in a short time. It's a valuable asset for businesses looking to streamline their production process and improve productivity. The paper tube machine's robust construction also ensures long-term durability, making it a worthwhile investment.

Adaptable Designs and Customization Options of Paper Tube Cutting Machine

Paper Tube Cutting Machines are not only efficient and precise but also highly adaptable and customizable. They are designed to cater to a wide range of industries and applications, making them a versatile choice for businesses of all sizes. Here’s a look at the adaptable designs and customization options of these machines:

Size and Capacity: Paper Tube Cutting Machines come in various sizes and capacities to accommodate different production needs. Whether you need to cut small paper cores for thermal rolls or large paper tubes for industrial packaging, there’s a machine designed to meet your specific requirements.

Cutting Mechanism: Depending on the thickness and material of the paper tube, you can choose from different cutting mechanisms. These include rotating blades, guillotine-style blades, or saw blades. Some machines even offer interchangeable blades for added flexibility.

Control System: Most paper core machine feature a digital control system that allows you to set the exact length for the cut. Some advanced models may also offer programmable controls, where you can save your settings for future use.

Automation Level: From semi-automatic to fully automatic models, you can choose the level of automation that suits your production process. Fully automatic machines can load, cut, and sort the tubes with minimal human intervention, saving time and labor costs.

Custom Features: Many manufacturers offer custom features to meet unique business needs. These may include special safety features, dust extraction systems, automatic sorting mechanisms, and more.

With these adaptable designs and customization options, Paper Tube Cutting Machines can be tailored to fit your business needs perfectly. They offer a practical and efficient solution to cut paper tubes or cores accurately and quickly, enhancing your production efficiency and profitability.

Advanced Cutting Mechanisms in Our Paper Tube Cutting Machine

Our Paper Tube Cutting Machine stands as a pinnacle of precision and efficiency with its advanced cutting mechanisms. Specifically engineered for cutting paper tubes or cores into exact lengths, this specialized equipment plays a pivotal role across diverse industries. From textiles to paper, printing, and packaging, its versatility meets the demands of varied applications. The machine incorporates cutting-edge technology, ensuring accuracy and reliability in every operation. Whether crafting customized tubes for packaging or contributing to the seamless production processes in printing, our Paper Tube Cutting Machine signifies a commitment to excellence, streamlining workflows and enhancing overall productivity across multiple sectors. less

May 8

-

wzcfmachine wzcf machine added new photos.

Paper Tube Making Machine

https://www.wzcfmachine.com/products/paper-tube-making-machine/

#paper #tube #making #machine #suppliers

The Chuangfeng paper tube manufacturing machine is a high-performance, efficient machine designed for the production of... morePaper Tube Making Machine

https://www.wzcfmachine.com/products/paper-tube-making-machine/

#paper #tube #making #machine #suppliers

The Chuangfeng paper tube manufacturing machine is a high-performance, efficient machine designed for the production of paper tubes. This paper pipe-making machine is renowned for its high-speed operation, precision engineering, and reliable performance. It is capable of producing a large number of paper tubes quickly and efficiently, making it an ideal choice for businesses in various industries such as packaging, textiles, and more.

Paper Tube-Making Machine Features:

The paper pipe making machine are suitable for Large & Thick cores like Stretch Film cores and Strong Industrial paper tubes & cores etc.

The main structure is constructed using thicker steel, which undergoes re-cutting and welding processes, ensuring enhanced stability and strength of the machine.

The main transmission utilizes gear speed reduction, resulting in low noise, minimal heat generation, high revolutions, and high torque.

The main motor employs a Vectorial high-torque inverter for speed adjustment.

It is outfitted with a hydraulic device for belt tension adjustment, featuring sensors for both belt tension and angle, allowing for automatic adjustments.

The machine is equipped with a synchronous cutting system, employing high-precision ball screws and high-performance servo motor drive for the cutting table.

A pulse length fixation control system, coupled with front feedback compensation functionality, ensures consistent length production across varying speeds.

Contact Chuangfeng for the paper tube-making machine price price!

Revolutionizing Sustainable Packaging with China Paper Tube Making Machines

Transform your brand's packaging sustainability effortlessly with our state-of-the-art Paper Tube Making Machines. Ideal for various applications, the paper pipe machine caters to industries such as cosmetics, food, and pharmaceuticals. Customize the diameter, length, and design of paper tubes to suit your product specifications. Revolutionize your cosmetic line by presenting products in eco-friendly paper tubes, promoting a luxurious yet sustainable image. In the food industry, our kraft paper tube-making machines enable the creation of sturdy, grease-resistant paper tubes for snacks and confectionery. For pharmaceuticals, ensure the safe and eco-conscious packaging of medicines.

Beyond versatility, our paper pipe-making machines significantly reduce waste and carbon footprint, contributing to a circular economy. Embrace the innovation of sustainable packaging that not only meets industry standards but exceeds them. Upgrade your packaging strategy with our Paper Tube Making Machines and make a lasting impression as an environmentally responsible brand, meeting the demands of conscious consumers. less

May 8

-

wzcfmachine wzcf machine added new photos.

Paper Tube Machine

https://www.wzcfmachine.com/products/paper-tube-machine/

#paper #tube #packaging #machine

Introducing our high-quality Paper Tube Machine, a perfect solution for all your paper tube production needs. This paper tube-forming machine... morePaper Tube Machine

https://www.wzcfmachine.com/products/paper-tube-machine/

#paper #tube #packaging #machine

Introducing our high-quality Paper Tube Machine, a perfect solution for all your paper tube production needs. This paper tube-forming machine is designed to produce paper tubes with precision and efficiency. It's capable of producing 20-100 paper tubes per minute, ensuring high productivity for your business. With its robust construction and easy operation, our paper pipe machine guarantees durability and reliability. Invest in our Paper Tube Machine and experience a significant boost in your production process.

As a professional paper tube machine manufacturer, Chuangfeng has decades of experience in paper tube machine projects, like the production line of food paper cans, potato paper cans, textile paper tubes, industrial paper tubes, etc. A comprehensive automatic tube-filling machine line to meet your needs.

Paper Tube Forming Machine Performance & Characteristics

The paper tube forming machine are suitable for Large & Thick cores like Stretch Film cores and Strong Industrial paper tubes & cores etc.

The main motor of the paper tube packaging machine is equipped with variable frequency speed regulation; and a touchscreen man-machine interface. Easy for parameters setting & operating.

The Servo motor synchronism tracking cutting system lets the core pipe-making machine cut at a higher precision; with an error of ≤ 0.15mm.

All the brands of components like Motor; Inverter; PLC; and Touch Screen can be customized.

Contact us for the paper tube machine price!

Test Standard of Paper Tube Machine

Complies with the provisions of the following European directives:

Machinery Directive 2006/42/EC

Electromagnetic Compatibility Directive 2014/30/EU

EN ISO 12100:2010

EN 415-10:2014

EN 60204-1:2018

EN IEC 61000-3-2:2019+A1:2021

EN 61000-3-3:2013+A2:2021

EN IEC 61000-6-1:2019

EN IEC 61000-6-3:2021 less

May 8

-

weihualaser .com

CO2 LASER CUTTING MACHINES FOR MDF

https://www.weihualaser.com/co2-laser-cutting-machines-for-mdf.html

#mdf #laser #machine

CO2 laser cutting machines are widely used in MDF. MDF is a common wood composite material with a uniform density and smooth... moreCO2 LASER CUTTING MACHINES FOR MDF

https://www.weihualaser.com/co2-laser-cutting-machines-for-mdf.html

#mdf #laser #machine

CO2 laser cutting machines are widely used in MDF. MDF is a common wood composite material with a uniform density and smooth surface.

May 8

-

hijcoffeepack TRUSTAR PHARMA&PACKING EQUIPMENT CO.,LTD

TMB-200 AUTOMATIC OVERWRAPPING MACHINE FOR SALE

The Machine is a specialized piece of equipment used for wrapping products in a protective film or overwrap. It is designed to automate the packaging process and ensure efficient and precise wrapping... moreTMB-200 AUTOMATIC OVERWRAPPING MACHINE FOR SALE

The Machine is a specialized piece of equipment used for wrapping products in a protective film or overwrap. It is designed to automate the packaging process and ensure efficient and precise wrapping operations. The automatic overwrapping machine is equipped with advanced technology and features, such as adjustable speed, to accommodate different product sizes and materials. Automatic overwrapping machine can handle a wide range of products, including boxes, trays, and other similar items, and swiftly wrap them in a protective film. In addition to automatic overwrapping machines, HIJPACK also offers different types of cellophane machines for sale.

The Features of the TMB-200 Automatic Overwrapping Machine

The automatic overwrapping machine has a compact and rational structure, advanced and stable performance, and is easy to operate and maintain.

The automatic overwrapping machine adopts a multifunctional digital frequency converter with step-less speed regulation.

The mold replacement of an automatic overwrapping machine is convenient and flexible.

The automatic overwrapping machine has functions such as automatic feeding and automatic counting.

The transmission part of the automatic overwrapping machine is equipped with various protective devices and fault prompts.

Applications Of The TMB-200 Automatic Overwrapping Machine

Pharmaceutical Packaging: HIJPACK’s automatic overwrapping machines are pivotal in the pharmaceutical industry, wrapping medicine boxes to ensure tamper evidence and product integrity. This application is critical for consumer safety and regulatory compliance, offering a barrier against contamination and extending product shelf life.

Food and Beverage Sector: In the food and beverage industry, HIJPACK’s automatic overwrapping machines package items like tea boxes and snacks, providing a protective seal that maintains freshness and flavor. The clear, tight wrap also improves shelf appeal, attracting consumers with its neat presentation.

Cosmetics and Personal Care Products: For cosmetics and personal care items, including perfumes and creams, HIJPACK’s automatic overwrapping machines add a protective layer against external contaminants, while enhancing the product’s premium appearance. This is essential in a market where packaging significantly influences consumer choices.

Specifications of the TMB-200 Automatic Overwrapping Machine

Model TMB200

Packaging speed 30-70bag/min

Packaging size Min:50x20x10 mm

Max:180x100x50 mm

Packaging material BOPP PVC

Power supply 220V 50HZ

Total power 4.5KW

Dimension 2100X750X1550 mm

Machine weight 650 KG

#automatic #overwrapping #machine

https://www.hijcoffeepack.com/products/tmb-200-automatic-overwrapping-machine.html less

Apr 8

-

hijcoffeepack TRUSTAR PHARMA&PACKING EQUIPMENT CO.,LTD

DXDK600 BACK SEAL PACKING MACHINE

DXDK600 back seal packing machine is a type of packaging machine that is specifically designed to create a back seal on packages. It is commonly used for packaging various products such as food items, pharmaceuticals,... moreDXDK600 BACK SEAL PACKING MACHINE

DXDK600 back seal packing machine is a type of packaging machine that is specifically designed to create a back seal on packages. It is commonly used for packaging various products such as food items, pharmaceuticals, cosmetics, and more.

The Features of the DXDK600 Back Seal Packing Machine

Sachet Making and Packaging: The machine is capable of making sachets, filling them with the desired product, sealing them, punching holes if required, counting the sachets, and printing batch numbers automatically.

Servo Motor Control: The machine utilizes a servo motor controlled by a computer to perform various functions such as pulling the sachet, tracking the eye mark for accurate positioning, determining the sachet length, and making the sachet. This ensures stable operation and accurate detection.

Back Seal and Angled Design: Sachets are sealed at the back, providing a secure and airtight seal. The four angles of the two sides of the sachet can be cut to a right angle or fillet, giving them a visually appealing and professional appearance. Additionally, an oblique easy tear design is incorporated, allowing users to conveniently open the sachets.

Optional Coding Methods: The machine offers three optional coding methods for marking the sachets. These include steel letter coding, laser coding, and ribbon coding. This allows for customization and flexibility in meeting specific coding requirements.

Specifications of the DXDK600 Back Seal Packing Machine

Model DXDK600

Max output 450pcs/min

Packing material Aluminum/plastic, paper/plastic, plastic/plastic composite film

Packing amount 0.4g-50g(0.8-100ml)

Core diameter 70-72 mm

Max width 600 mm

Max outer diameter 500 mm

Power supply 380V 50HZ

Total power 10KW

Dimension 1600X1550X2550 mm

Machine weight 1000 KG

#back #sealing #machine

https://www.hijcoffeepack.com/products/dxdk600-back-sealing-machine.html less

Apr 8

-

hijcoffeepack TRUSTAR PHARMA&PACKING EQUIPMENT CO.,LTD

DXDF320 STICK PACKING MACHINE FOR POWDER

A Stick Packing Machine for Powder is a specialized packaging device designed to fill and seal stick packs with powdered products. It’s widely used in industries like food, pharmaceuticals, and cosmetics for... moreDXDF320 STICK PACKING MACHINE FOR POWDER

A Stick Packing Machine for Powder is a specialized packaging device designed to fill and seal stick packs with powdered products. It’s widely used in industries like food, pharmaceuticals, and cosmetics for packaging products such as coffee, spices, protein powders, and pharmaceutical powders. This machine ensures precise filling, reducing waste and enhancing product presentation.

The Features of DXDF320 Stick Packing Machine For Powder

The machine consists of various stations including a hopper, feeding motor, stirring screw, packing screw, secondary storage bin, packaging material unwinding, packaging material cutting, longitudinal sealing, horizontal sealing, and horizontal cutting.

The measuring mechanism transfers the material to the secondary storage bin using a left and right two-way screw.

A servo motor drives the screw to push the material into the packaging bag, ensuring quantitative metering.

The capacity requirement can be adjusted by setting parameters on the touch screen, such as changing the screw speed and circle number.

The metering method is primarily used for filling powder materials of more than 100 mesh.

It offers advantages such as fast running speed, high measuring precision, and easy adjustment.

Specifications of the DXDF320 Stick Packing Machine For Powder

Model DXDF320

Max output 130 pcs/min

Scope of substance ≥100 mesh

Bag lanes 4 lines

Range of measurement 1-20g(1-40ml)

Power supply 380V 50HZ

Dimension 1100X1200X2300 mm

Machine weight 900 KG

#powder #stick #pack #filling #machine

https://www.hijcoffeepack.com/products/dxdf320-stick-packing-machine-for-powder.html less

Apr 8

-

hijcoffeepack TRUSTAR PHARMA&PACKING EQUIPMENT CO.,LTD

AUTOMATIC COFFEE CAPSULE FILLING MACHINE

WHAT IS COFFEE CAPSULE FILLING... moreAUTOMATIC COFFEE CAPSULE FILLING MACHINE

WHAT IS COFFEE CAPSULE FILLING MACHINE?

A coffee capsule filling machine also named coffee capsule packing machine, is a type of packaging machine specifically designed for filling coffee capsules or pods. The coffee capsule packaging machine automates the process of filling individual capsules with ground coffee or instant coffee. These automatic coffee capsule filling machines are highly efficient and can handle high volumes of coffee capsules, allowing for faster production and increased productivity. HIJPACK packaging machinery manufacturer offers a variety of coffee capsule packing machines, coffee capsule powder filling machines, k cup filling machines, if you want to know more about automatic coffee capsule filling machines and coffee capsule filling machine prices, please do not hesitate to contact us.

TYPES OF AUTOMATIC COFFEE CAPSULE FILLING MACHINES

CF50 Multifunctional Single Head Coffee Capsule Filling and Sealing Machine

CF80 Coffee Capsule High Speed Canning Sealing Machine

CF120 Multifunctional Coffee Capsule 2 Lanes Caning, Sealing and Capping Machine

CF140 Disk Type Double Head Filling and Sealing Buckle Cover Integrated Machine

CF240 Multifunctional Coffee Capsule 4 lanes Sealing Machine

HOW TO MAINTAIN THE AUTOMATIC COFFEE CAPSULE FILLING MACHINE

To maintain an automatic coffee capsule filling machine, the following steps can be followed:

01

Regular Cleaning

Clean the coffee capsule filling machine regularly to remove any coffee residue or debris that may accumulate during the filling process. Use appropriate cleaning agents and follow the manufacturer’s instructions for cleaning.

02

Lubrication

Lubricate the moving parts of the coffee capsule packaging machine as per the manufacturer’s recommendations. This helps to reduce friction and ensure smooth operation.

03

Inspection and Replacement of Parts

Regularly inspect the coffee capsule packaging machine for any worn-out or damaged parts. Replace any faulty components promptly to avoid further damage to the machine and ensure optimal performance.

04

Calibration

Periodically calibrate the coffee capsule packing machine to ensure accurate filling of coffee capsules. This involves adjusting the settings and measurements to maintain consistency in the filling process.

05

Training and Operator Knowledge

Provide proper training to the coffee capsule packing machine operators to ensure they understand the correct operation and maintenance procedures. This will help prevent any mishandling or misuse of the machine.

06

Preventive Maintenance

Implement a preventive maintenance schedule to address any potential issues before they become major problems. This may include routine inspections, cleaning, and servicing of the coffee capsule packaging machine.

07

Follow Manufacturer’s Guidelines

Always refer to the manufacturer’s guidelines and recommendations for maintenance and troubleshooting. They will provide specific instructions tailored to the particular model of the coffee capsule filling machine.

By following these maintenance practices, the coffee capsule filling machine can be kept in good working condition, ensuring consistent and efficient filling of coffee capsules.

THE IMPORTANCE OF AUTOMATIC COFFEE CAPSULE FILLING MACHINES

Automatic coffee capsule filling machines play a crucial role in the coffee industry, particularly in the production of single-serve coffee capsules. Here are some key reasons highlighting the importance of these coffee capsule packing machines:

Efficiency and Productivity: Coffee capsule filling machines automate the process of filling coffee capsules, significantly improving efficiency and productivity. These automatic coffee capsule filling machines can fill a large number of capsules in a short period, reducing manual labor and increasing production output.

Consistency and Accuracy: Automatic coffee capsule filling machines ensure consistent and accurate filling of coffee capsules. The coffee capsule packaging machines are designed to dispense precise amounts of coffee grounds or instant coffee into each capsule, ensuring uniformity in taste and quality across all capsules.

Preservation of Freshness and Aroma: Coffee capsules are designed to preserve the freshness and aroma of coffee. Filling machines play a vital role in maintaining the quality of the coffee by sealing the capsules tightly, preventing exposure to air, moisture, and light that can degrade the coffee’s flavor and aroma.

Hygiene and Food Safety: Coffee capsule filling machines are designed with hygiene and food safety standards in mind. The coffee capsule packaging machines are equipped with features such as stainless steel construction, easy-to-clean surfaces, and sanitary filling mechanisms, ensuring that the coffee remains safe for consumption.

Customization and Flexibility: Coffee capsule filling machines offer customization options, allowing coffee manufacturers to cater to different consumer preferences. These automatic coffee capsule filling machines can handle various capsule sizes, coffee blends, and even accommodate special requests such as decaffeinated or flavored coffee.

AUTOMATIC COFFEE CAPSULE FILLING MACHINE FEATURES

Customization and Versatility: This coffee capsule packing machine is highly customizable, catering to various packaging needs. The coffee capsule filling machine supports both premade lids and roll film punch options for sealing, making it adaptable to different packaging designs and requirements. The ability to connect with vertical packing machines or flow wrappers further enhances its versatility, making it a popular choice for coffee capsule packaging.

Advanced Control and Operation: Equipped with a PLC control system and a touchscreen interface, the coffee capsule packaging machine offers easy and intuitive operation. This advanced control system ensures precise filling and sealing processes, reducing the likelihood of errors and improving overall efficiency.

High Precision Filling: The coffee capsule packing machine features a servo-driven auger filler, known for its high fill accuracy. This ensures that each coffee capsule is filled with the exact amount of coffee, maintaining consistency across all products. The drill’s height is adjustable, facilitating easy installation and accommodation of different capsule sizes.

Efficient Capsule Handling: With an automatic cup feeder and a storage area for a large number of cups, the coffee capsule powder filling machine ensures a continuous supply of capsules for filling. This automatic coffee capsule filling machine also includes a ‘no cup, no fill’ feature, which prevents wastage of coffee by ensuring that the machine only operates when capsules are present for filling.

Safety and Maintenance: This automatic coffee capsule filling machine’s horizontal design not only facilitates easy maintenance but also incorporates safety features such as a door open stop safety protect device. This ensures that the machine automatically stops operation if the door is opened during operation, protecting the operator from potential harm. Additionally, the moveable mould and pneumatic-driven mould design contribute to the coffee capsule filling machine’s stability and ease of maintenance.

FAQS OF COFFEE CAPSULE FILLING MACHINE

How fast can coffee capsule filling machines fill and seal capsules?

The speed at which coffee capsule filling machines can fill and seal capsules can vary depending on the specific machine and its capabilities. However, on average, these coffee capsule filling machines can fill and seal capsules at a rate of around 60 to 80 capsules per minute.

Are coffee capsule filling machines easy to operate?

Yes, the coffee capsule filling machines typically have intuitive controls and clear instructions, making it simple for users to understand and navigate the machine. Some coffee capsule making machines even have automated features that streamline the filling and sealing process, further enhancing ease of use. With a little bit of training and familiarity with the coffee capsule packaging machine’s functions, operators can quickly and efficiently fill and seal coffee capsules without much difficulty.

Can coffee capsule filling machines be customized with branding elements?

Yes, our coffee capsule packaging machines support customized branding elements. This means that the coffee capsule packing machines can be designed and modified to incorporate specific branding elements such as logos, colors, and graphics. Customization options may vary depending on the manufacturer and model of the automatic coffee capsule filling machine. By adding branding elements, businesses can create a cohesive and recognizable brand identity for their coffee capsules, enhancing their marketing and branding efforts.

Are automatic coffee capsule filling machines environmentally friendly?

Yes, our automatic coffee capsule filling machines are energy-efficient, consuming less electricity during operation. This helps to reduce the overall environmental impact. It is important to research and choose coffee capsule packing machines that prioritize environmental sustainability, such as those that use eco-friendly materials and have energy-efficient features.

#coffee #capsule #powder #filling #machine

https://www.hijcoffeepack.com/products/coffee-capsule-filling-machine/ less

Apr 8

-

hijcoffeepack TRUSTAR PHARMA&PACKING EQUIPMENT CO.,LTD

CELLOPHANE WRAPPING MACHINE

WHAT IS CELLOPHANE WRAPPING... moreCELLOPHANE WRAPPING MACHINE

WHAT IS CELLOPHANE WRAPPING MACHINE?

This machine is widely used in the packaging of various single large box items or the collective film packaging of multiple small box items (with gold wires) in industries such as pharmaceuticals, health care products, food, cosmetics, stationery, and audio-visual products.

The work of this machine is completed by a series of servo motors inside the machine driving various connecting rods and components. It adopts multi-functional digital display, variable frequency stepless speed regulation, PLC programming control technology, automatic box feeding, automatic counting, and touch display. Human-machine interface, suction and film falling; and can be used in conjunction with other production lines.

TYPES OF CELLOPHANE WRAPPING MACHINE

TMB-200 Automatic Overwrapping Machine

TMB-200 Automatic Overwrapping Machine

TMB-300 Automatic Transparent Film 3D Packaging Machine

TMB-300 Automatic Transparent Film 3D Packaging Machine

TMB-450 Full Servo 3D Packaging Machine

TMB-450 Full Servo 3D Packaging Machine

THE BENEFITS OF CELLOPHANE WRAPPING MACHINE

01

Efficiency

Cellophane wrapping machines can wrap products faster and more efficiently than manual wrapping.

02

Consistency

They ensure uniform and professional-looking wrapping, enhancing product presentation.

03

Cost-Effective

These machines reduce labor costs and material waste, saving money in the long run.

04

Versatility

They can wrap a wide range of products, from food items to cosmetics.

05

Hygiene

They provide a sanitary way to package products, reducing contamination risks.

FAQS OF CELLOPHANE WRAPPING MACHINE

How efficient is a Cellophane Wrapping Machine?

Cellophane Wrapping Machine has excellent packaging efficiency.

The maximum speed can reach 130 boxes/min, and the minimum speed can reach 20 boxes/min according to the box size.

How does a Cellophane Wrapping Machine work?

The machine through the motor drive belt conveyor continuous transmission of small boxes through the vertical box mechanism to the designated position, the cylinder to push a certain number of small boxes to the lifting position, touch the proximity switch, the machine began to run periodically.

The cylindrical transparent film installed on the bracket is guided by the paper guide tube, the paper feed tube and the traction of the rubber roller, cut by the rotary upper cutting knife, and transferred by the belt to the lifting position and the box.

Lift the top plate to lift the bar and box, so that the bar and box reach the highest position of the transparent film, forming the "冂" shaped packaging; When the advancing mechanism is in contact with the strip and box, the bottom folding plate and the end folding device fixed at the bottom of the mechanism fold the bottom long side and the end short side of the strip and the back side of the box respectively; With the advance of the propulsion mechanism, the long side of the bottom and the short side of the end are folded simultaneously by the forming channel; The bottom heater heat seals the bottom long edge; Then the inner and outer heating plates at both ends heat seal the end of the strip and box; The strip and box are reshaped through the lower heating plate, and the transparent film packaging of the strip and box is complete.

What types of products can be wrapped with a Cellophane Wrapping Machine?

Cellophane Wrapping Machine can wrap a wide range of products. Can be for the packaging box for the outside of the film packaging, including cosmetics box, perfume box, cigarette box, poker box, medicine box, etc., can be for a box for film, can also be for multiple boxes for film packaging.

#cellophane #machine #for #sale

https://www.hijcoffeepack.com/products/cellophane-wrapping-machine/ less

Apr 8

-

hijcoffeepack TRUSTAR PHARMA&PACKING EQUIPMENT CO.,LTD

AUTOMATIC CARTONING MACHINE SUPPLIER

WHAT IS AUTOMATIC CARTONING... moreAUTOMATIC CARTONING MACHINE SUPPLIER

WHAT IS AUTOMATIC CARTONING MACHINE?

An automatic cartoning machine also named auto cartoner machine, is a packaging equipment, which inserts products into cartons automatically. The auto cartoner machine has combined the function, sucking cartons, forming cartons, folding leaflets, products, and leaflets together into cartons, printing batch numbers, sealing boxes, and rejecting and transferring the final products out. The automatic cartoning machine can reduce the working intensity and save labor force costs; and improve automation and production efficiency. The auto cartoner machine is widely applied to carton packaging of pharmaceuticals,food, cosmetics, stationery hardware, and so on. HIJPACK is the one of famous cartoning machine suppliers, which offers a variety of automatic cartoning machines, automatic box packing machines, and automatic cartons, if you want to know more about auto cartoner machines and cartoning machine prices, please do not hesitate to contact us.

TYPES OF AUTOMATIC CARTONING MACHINE

WZTS-60 Vertical Opening Cartoning Machine

WZTS-120 Vertical Cartoning Machine

WZTS-130 Horizontal Cartoning Machine

THE BENEFITS OF AUTO CARTONER MACHINE

01

Famous brand

Electrical components of auto cartoner machines are Internationally famous brands, such as PLC touch screens, frequency inverters, etc.

02

Human-machine

The auto cartoner machine adopts a human-machine operation system.

03

Automatically

The automatic cartoning machine automatically stop when machine is overload.

04

Automatically

The automatic cartoning machine automatically rejects the lacking package product and leaflet.

05

Easy operation

The auto cartoner machine automatically displays trouble, Alarm, and count finished products.

Stable performance, operation is easy.

WORKING PRINCIPLE OF THE AUTOMATIC CARTONING MACHINE

01

Product feeding

The automatic cartoning machine receives products from the production line, such as bottles, tubes, or blister packs.

02

Carton forming

Flat cardboard sheets are transformed into cartons through folding and gluing.

03

Product insertion

Mechanical arms or robotic systems accurately place the products into the formed cartons.

04

Leaflet insertion

If required, the auto cartoner machine can insert leaflets or instruction manuals into the cartons.

05

Carton closure

Various methods like hot melt glue, tuck-in flaps, or adhesive tapes are used to seal the cartons.

06

Quality control

Sensors and vision systems ensure proper product insertion, carton closure, and overall quality control.

07

Carton ejection

Defective or improperly filled cartons are automatically rejected from the production line.

08

Speed and efficiency

The auto cartoner machine operates at high speeds, enhancing productivity.

09

Versatility

Auto cartoner machines can handle a wide range of product sizes and shapes, making them suitable for various industries.

010

User-friendly interface

The cartoning packaging machine features a user-friendly control panel for easy monitoring and adjustment.

AUTOMATIC CARTONING MACHINE STANDARD FEATURES

01

Innovative Design for Efficiency

At the heart of the automatic cartoning machine's design, the cartoning machine features a rotary suction box way, which optimizes the picking and placing of cartons, ensuring a smooth and continuous operation. Auto cartoner machine, combined with an auxiliary box opening device, guarantees that each carton is precisely opened and ready for product insertion, contributing to the machine’s overall speed and efficiency.

02

Intelligent Control System

Equipped with a state-of-the-art PLC control system and an intuitive HMI (Human-Machine Interface), the Automatic Cartoning Machine offers unparalleled control over the packaging process. This advanced system allows for easy monitoring and adjustments on the fly, ensuring that operations run smoothly and efficiently, with minimal downtime.

03

Durable and Hygienic Construction

The auto cartoner machine boasts a full 304 stainless steel cover, not only providing a robust and durable exterior but also ensuring compliance with the highest hygiene standards. This makes it ideal for industries where cleanliness and product integrity are paramount, such as food and pharmaceuticals.

04

Advanced Safety Features

An advanced overload protection system is a testament to the machine’s sophisticated design, safeguarding against potential damage caused by overloading. This automatic cartoning machine's feature ensures the longevity of the machine and protects the products being packaged, as well as the operators.

05

Flexible and User-Friendly Operation

The automatic box filling machine’s size-changing structure, equipped with a ruler, allows for quick and easy adjustments to accommodate different carton sizes. This flexibility is further enhanced by the “no product, no suction box” function, which ensures that the machine operates only when products are present for packaging, reducing waste and improving efficiency.

FAQS OF AUTOMATIC CARTONING MACHINE

How does an Automatic Cartoning Machine work?

On line product feeding and detecting, leaflet fold(1-4folds) and feeding, leaflet detecting, canton opening and forming, products and leaflet pushing into carton, printing batch number, sealing carton with tuck-in or hot melt glue device.

Automatically reject lacking of leaflet or product and finished product out.

What types of products can be packaged with an Automatic Cartoning Machine?

Automatic Cartoning machine can package many products, such as medicine packaging, food packaging, cosmetics packaging, daily necessities packaging, coffee packaging, toy packaging and so on, widely used in various fields.

What is the capacity of an Automatic Cartoning Machine?

The maximum encasing speed of the automatic cartoning machine can reach 120 boxes/min, and the minimum encasing speed can reach 30 boxes/min. Meet the requirements of different factories for packing speed.

#cartoning #machine #suppliers

https://www.hijcoffeepack.com/products/automatic-cartoning-machine/ less

Apr 8

-

hijcoffeepack TRUSTAR PHARMA&PACKING EQUIPMENT CO.,LTD

Packaging and Machinery Solutions

The Evolution of Daily Necessities Packaging... morePackaging and Machinery Solutions

The Evolution of Daily Necessities Packaging Machines

The evolution of daily necessities packaging making machines has transformed the consumer goods industry. From manual to automated systems, these machines have become more efficient, precise, and versatile. They can handle a variety of packaging materials and formats, ensuring products are attractively and securely packaged. Innovations like smart sensors and AI have further enhanced their performance, enabling real-time monitoring and adjustments for optimal results. This continuous evolution is driving productivity, reducing waste, and meeting the ever-changing consumer demands.

The Application of Packaging Machines in Daily Necessities

Packaging machines play a pivotal role in the daily necessities industry. They automate the process of wrapping, sealing, and labeling products, enhancing efficiency and productivity. HIJPACK packaging machinery manufacturers' machines can handle a variety of packaging materials and sizes, ensuring flexibility and versatility. They also ensure precise filling and accurate labeling, reducing waste and errors. By streamlining the packaging process, these machines help manufacturers meet high-volume demands, maintain product quality, and achieve cost-effectiveness.

#liquid #pouch #filling #machine

https://www.hijcoffeepack.com/packaging-machinery-solutions-in-daily-necessities.html less

Apr 8

-

Mont Drive

Revolutionizing Vertical Transport: The Cutting-Edge Passenger Elevator Machine from Mont Drive

In the bustling metropolises of today, vertical transport is more than just a convenience—it's a necessity. Skyscrapers dominate skylines, and the... moreRevolutionizing Vertical Transport: The Cutting-Edge Passenger Elevator Machine from Mont Drive

In the bustling metropolises of today, vertical transport is more than just a convenience—it's a necessity. Skyscrapers dominate skylines, and the efficiency and safety of elevators are paramount to urban life. In this regard, Mont Drive emerges as a pioneering force, redefining the standards of Gearless Passenger Elevator Machines. Mont Drive is at the forefront of innovation in the elevator industry. With a commitment to excellence and a focus on advancing technology, Mont Drive has introduced a new generation of Gearless Passenger Elevator Machines that are revolutionizing vertical transport systems worldwide.

At the heart of Mont Drive's Gearless Passenger Elevator Machine is its advanced motor technology. By leveraging state-of-the-art motor designs, Mont Drive elevators achieve unprecedented levels of efficiency and speed.

To know more details regarding the Gearless Passenger Elevator Machine, visit Mont Drive's Website or call at +919999467601.

For more details visit:- https://bit.ly/3xgtyCV